Day 4: Settling into the Swing of Things

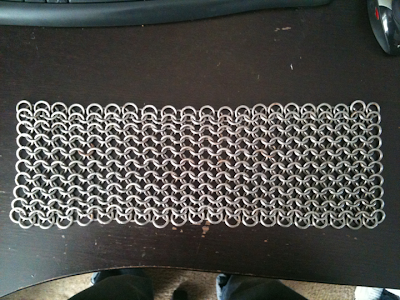

Chainmaille progression was virtually nil today. Tweaked a few things to ensure that rings were butted tightly and that the pattern was even on the piece that I am calling "Front Yoke". I got about 55 rings into "Rear Yoke" before setting it down to work on leather. I'm finding that if I work on one thing for too long, the muscles I'm using for that particular task get extremely sore and then work over the next few days is painful.

I started punching holes in my lamellar plates in earnest today. Brent and I had already marked all the plates with the hole pattern, and I bought a 5/32" round hammer punch at Tandy to make the holes. It's a little bigger than Brent's 9/64" punch, but the visual difference should be invisible once everything is dyed and starts getting laced together.

About 20 plates in (read: 160 holes punched), I started noticing this black grit all over the table and my pieces. A little investigation revealed that it was bits of the 1-pound rubber mallet I was using in conjunction with my punch. Each strike was ripping off bits of rubber, and each hole took between 4 and 6 strikes to make, so the mallet was quickly disintegrating.

I went to Mall-Wart to pick up a polyurethane-headed mallet like Brent got from Tandy, but no such luck. All the soulless mega-mart had were more rubber mallets. On the way back home, I drove by an AutoZone and thought, "They have mallets at auto parts stores, maybe they have non-rubber ones!" And I was so right. There in the tool section was a one-piece, cast urethane dead-blow hammer, a lovely 2 pounds with steel shot in the head to add force and reduce recoil vibration. It was a little pricey at $13, but it looked like just what I needed, so I was willing to drop the dough.

I got back to the house with the mallet and tried it out, checking after each hole for marring of the striking surface or any signs that the mallet wasn't going to last. But I shouldn't have even worried, because aside from some extremely minor indentations, the mallet still looked new after punching another 20 pieces. Now keep in mind, the rubber mallet wasn't brand new, but it was in almost-pristine condition when I started. Here's a comparison of the two mallets after they each punched 160 holes:

The angle of the photograph actually hides some of the damage, because the rubber mallet (on the left) is actually indented over an 1/8" of an inch into the surface, but the dead-blow mallet has barely any marks.

Another benefit of the new mallet is that at double the weight and with a harder striking face to transfer more force into the punch, each hole takes 1 or maybe 2 (on the thickest plates) strikes to punch the hole, cutting down my time spent on each piece. With the rubber mallet, it was taking at least 90 seconds to punch each plate, now I'm creating all 8 holes in 30 to 45 seconds, and there's less repetitive motion strain on my wrist and elbow.

So with some anime playing on TV to keep me interested, I got down to work, setting up a rhythm to keep everything flowing nicely and at about midnight-30, I had a nice block of 100 plates fully punched and ready to dye tomorrow.

The plan tomorrow is to set up an assembly line of sorts. Brent and I will finish punching the other 200 cut plates, then design, mark and cut the pair panels for the shoulder straps as well as the 6 to 8 belts for the side closure.

After those are cut and punched, we will start the dye process. In a large bowl, we'll start submerging sets of 10 or so punched plates into the dye/water solution. I want to get a mottled effect on the armor, so once each set is submerged, pieces will be individually removed and excess dye dried off before the next piece is pulled from the dye bath, so the pieces from each set which are pulled out first will be lighter than the last pieces to be removed. There will be no purposeful pattern to the assembly of the pieces based on color, once they've been dyed they'll all just be thrown in a bag and selected one at a time at random to be added to the armor. The random selection will create a nice mottled effect to the finished vest. The shoulder straps and closure belts will be more traditionally dyed, using a foam brush, as I'm not too worried about their coloration.

Once dying is complete, we will start oiling each piece with neatsfoot oil and and begin lacing them together using suede cord, likewise oiled. I think the best method will be to oil each piece as it is selected for lacing, that way there is no confusion about which have been oiled or not.